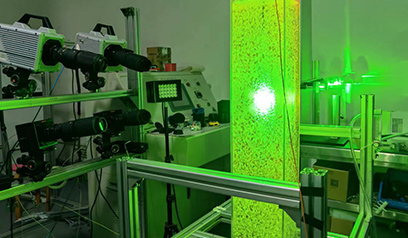

Laser Shock Peening (LSP), also known as laser peening, is a high-tech method that uses high power density and short-pulse lasers (in the range of 10 to 30 ns) to generate high-intensity shock waves on the material surface by applying an absorbing layer that absorbs the laser energy. This process induces high residual compressive stress, improves the initiation life of fatigue cracks, effectively reduces the driving force of fatigue crack propagation, and extends the fatigue crack propagation life. It enhances the fatigue resistance, wear resistance, and corrosion resistance of metal materials. LSP is known for its non-contact nature, absence of heat-affected zones, strong controllability, and significant strengthening effects.

Laser Shock Peening

Laser technology enhances the fatigue resistance, wear resistance, and corrosion resistance of metal materials

Detailed ConsultationDescription

Solution

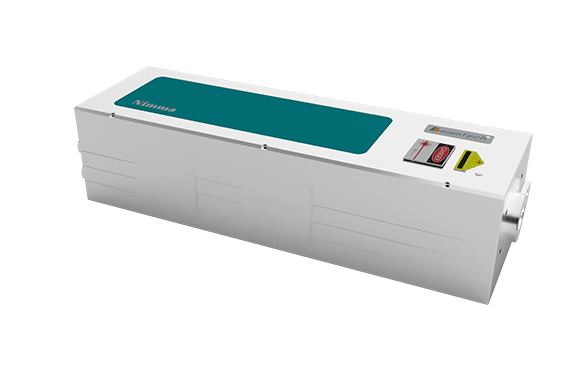

Beamtech’s SGR-Extra series Nd:YAG pulsed lasers are suitable for laser shock peening applications. Since 2008, we have provided customers with over 40 high-energy solid-state laser products with energies ranging from 5 J to 60 J.

The SGR-Extra series products offer single pulse energy ranging from 6 J to 60 J at a wavelength of 1,064 nm. They have high plasma generation efficiency in peening applications and provide a uniform flat-top beam distribution to ensure the consistent surface modification of the workpiece during peening.

These lasers are designed for long-term stable operation and ensure the effectiveness and reliability of the peening process. Beamtech’s user-friendly design allows for seamless integration with shock peening systems, facilitating system integration for peening applications.

Additionally, Beamtech can provide customized laser equipment tailored to the peening process, meeting customer needs by offering various solutions in external optical path design, single or dual path switching, and intelligent remote control.