Design Requirements for the Water Cooling System of Solid-State Lasers

Posting Date:2024-05-13

Views:626

Solid-state lasers generate a lot of heat when working, if not timely cooling, will seriously affect the service life of the equipment and working effect, and even cause serious damage to the equipment. Choosing the right laser water cooling system can greatly improve the service life of laser equipment and maximize the performance of laser equipment.

Cooling System Design Points

- System cooling power

The cooling power of the system needs to be based on the laser flash lamp pumping power, and take into account the heat exchange efficiency and duration of operation to choose. Can not just take the supplier's calibration of the cooling capacity as a reference basis, because different manufacturers may vary greatly in the definition of the cooling capacity of the standard, should be determined by the actual situation test conditions prevail, to avoid the actual cooling power is not enough.

- Cooling system flow and pressure

Solid-state laser cavity core has a small structure inside the design, must ensure that a certain amount of water flow in order to take away the heat generated in a timely manner. At the same time, the cavity core has a sealing ring structure, in order to protect the sealing of the cooling system, not to use excessive water pressure. Therefore, the design of the cooling system needs to ensure that the flow rate at the same time, does not exceed the maximum working pressure.

- Circulation Design Material Selection

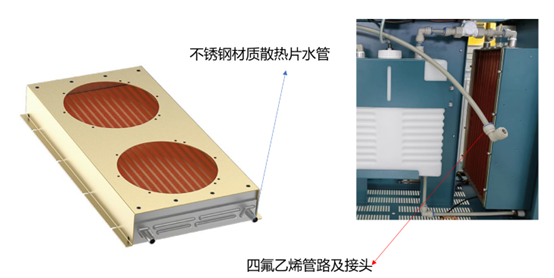

Stainless steel or PTFE is recommended for water piping systems to avoid piping that contains copper and other oxidizing corrosion-prone devices. If these devices oxidized, the formation of patina (alkaline copper carbonate Cu2(OH)2CO3), aluminum oxide (Al2O3) or iron oxide (Fe2O3) precipitated in the water pipe is easy to contaminate the optical cavity, resulting in reduced energy output of the laser.

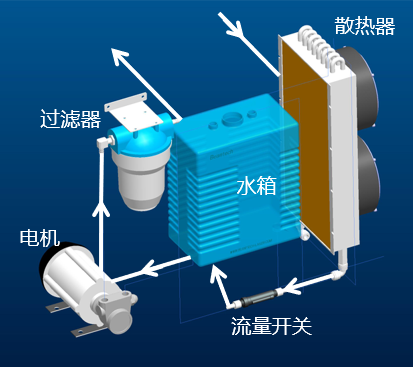

To summarize, for flash lamp pumped lasers in the field of medical cosmetology, we recommend the use of water circulation + heat exchanger heat dissipation, such as the use of compressor refrigeration, need to pay extra attention to the control of dew point temperature. As shown in the figure below:

Common Cooling System Problems

Regularly check the cooling water level and keep it at the proper level. Replace the coolingwater and filter element regularly.

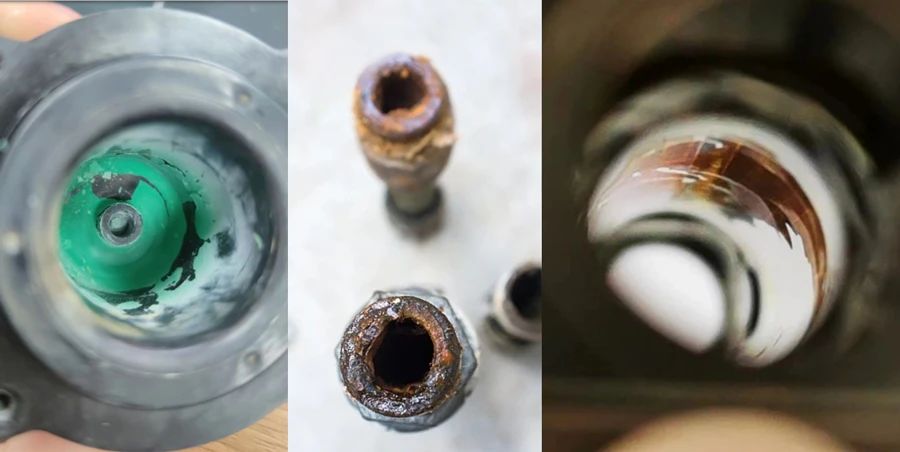

Preventing algae, bacteria and microbial growth in the cooling system water is very important, water-cooled system water system is not hermetically sealed, long-term use of exposure to the external environment, dust, fine particles and bacteria into the cold water leading to the deterioration of the water, resulting in the production of insoluble water substances attached to the inner wall of the water circuit of the laser, thus blocking the water circuit resulting in a decline in the flow of water, reducing the cooling effect. Therefore, regular replacement of cooling water is very necessary. The following figure shows the deterioration of distilled water in the pipeline. Water cooling system inside the water needs to be replaced regularly, the recommended replacement frequency of 3 months, the filter element according to the use of 3-6 months replacement, and regular cleaning of the laser and water system, you can use the "filled in water - the machine runs for a short period of time - - drain" operation, you can use "water - the machine runs for a short period of time - - drain" operation. -Drainage" operation, repeated 2-3 times.

Long periods of non-use of equipment, such as the Spring Festival shutdown or laser transportation must be emptied before the cooling water in the chiller, and compressed air will be compressed air will be included in the equipment, including lasers, chiller residual water blowing clean, to prevent internal icing or water leakage resulting in damage to the device. As the xenon lamp spectrum contains ultraviolet components, with a certain sterilization effect, if the device is not tried for a long time, the cooling water microorganisms and algae will grow rapidly, resulting in cooling water deterioration.

Used coolant other than distilled water

It is recommended that only distilled water (not deionized water, which does not require the addition of an algaecide) be used as the coolant. The use of deionized water will corrode the internal components of the chilled water system, and the algaecide will affect the working life of the internal components in the long run, so it is recommended to use only distilled water.

Improper use and storage of chillers in winter

In winter, the temperature difference between indoor and outdoor is large, after receiving the laser, it should be placed upright for more than 12 hours before turning on, if there is a chiller with the goods, the chiller also needs to be placed upright for more than 12 hours before turning on. When the ambient temperature is lower than 0 ℃ and long-term deactivation, in order to prevent the equipment from freezing and cracking, we need to carry out drainage operations. If the temperature is below 0 ℃ during storage or transportation without drainage operation, the water inside the laser will become larger when it condenses into ice, which will cause clogging of the pipeline, cracking of the cavity core inside the laser, and in serious cases, it will lead to scrapping of the laser beyond repair, resulting in huge losses.

Antifreeze is corrosive and is not recommended. If the laser must be used in an environment lower than 0℃, it is recommended to use 1:1 ratio of ethylene glycol and distilled water as coolant, but it must not be used for a long period of time, as long-term use will lead to a decrease in the efficiency of the laser. After the coolant is used, the pipeline must be cleaned with distilled water, the filter element must be replaced, and distilled water must be restored as the coolant.

A well-designed cooling system can keep the laser at a high performance for a long time. If you have any questions about the design and maintenance of water-cooling system, please contact us.